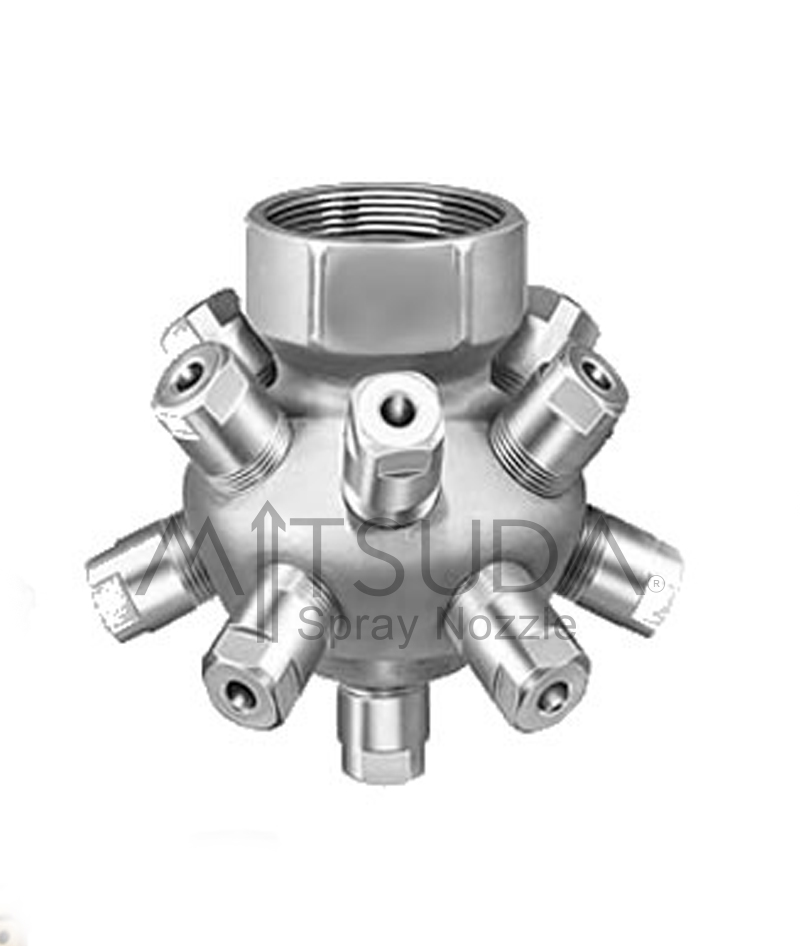

Tank Wash Nozzles

Tank washing nozzles range from the most basic fixed wash balls to models that can rotate around their own axis and wash 360 degrees. With a single tank washing nozzle selected according to the process, you can wash a small juice bottle or a giant tank with a diameter of 80 meters. While the nozzle rotates around its own axis, lubrication and lubrication occur automatically, thus providing a long-term maintenance-free operation.

While standard spraying angles of 90, 180, 270, 360 degrees provide solutions for almost all tank washing processes, the hygiene rules demanded by the food industry are met with standard AISI 316L material. In some tank washing nozzle models, special design quick connection alternatives are offered. The most important feature of these connections is that they are fully insulated and designed to prevent bacterial growth.

Thanks to the high impact water jet, washing, rinsing, stripping, disinfection can be done, and the inner walls of the tank can be scanned 360 degrees spherically.

There are 3 basic groups as tank wash nozzles:

• Motorized Driven Washing Nozzles • Fixed Washing Balls • Rotating Tank Washing Nozzles

The tank washing nozzles, which remove even the toughest sticky residues thanks to its consistent impacts in the range, help with the washing of tanks up to 30m in diameter. Tank washing nozzles provide all possible uninterrupted and intense flow. With its specially designed internal geometry system, it reduces the turbulence in the water and allows further development of flow integration. The better flow integration it provides increases impact severity and cleaning efficiency. The nozzles, which rotate 360 degrees around their axes, form a cross and cover all the inner surfaces of the tanks. Customizable nozzles on request and can be used for high integrations and concentrated chemical cycles or for low pressure high flow washing.